Clutch PTO Shaft – Superior and Reliable Performance | Buy Now

Product Features

The clutch PTO shaft, also known as the power take-off shaft, is a critical component of many industrial and agricultural machinery. It plays a vital role in efficiently transmitting power from the engine to PTO-driven implements. In this article, we will explore the characteristics and characteristics of the clutch PTO shaft and provide product descriptions of its individual components.

The clutch PTO shaft is designed to transfer power from the engine to the PTO driven implement. Its main feature is the ability to engage and separate the flow of power via a clutch mechanism. This feature allows the operator to control power delivery based on requirements. Clutch PTO shafts are commonly used on tractors, combine harvesters and other heavy machinery.

Let’s take a closer look at the product description of the clutch PTO shaft assembly:

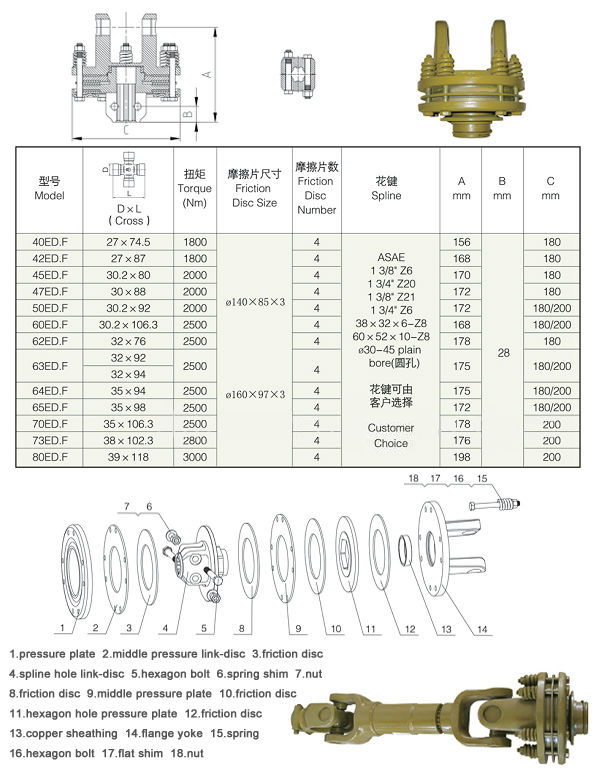

1. Pressure plate: The pressure plate is a key component that applies pressure to the clutch plates to engage or disengage them.

2. Medium-pressure connecting rod plate: This connecting rod plate serves to connect the pressure plate and clutch plate to provide smooth power transmission.

3. Friction disc: The friction disc is responsible for transmitting the engine's power to the PTO-driven implement. It experiences friction during engagement.

4. Spline hole connecting rod plate: The spline hole connecting rod plate provides a strong connection between the clutch PTO shaft and the implement.

5. Hexagonal bolts: Hexagonal bolts are used to fasten and fix various components of the clutch power output shaft.

6. Spring Spacers: Spring spacers are designed to provide flexibility and help maintain the pressure required for smooth power transfer.

7. Nut: The nut is used to fix the bolt to ensure the tightening of various components of the clutch power output shaft.

8. Copper sheath: The copper sheath is used to reduce friction and wear between moving parts to ensure a longer service life of the clutch power output shaft.

9. Flange yoke: The flange yoke is an important component that connects the clutch power output shaft to the implement, enabling efficient power transmission.

10. Spring: Spring helps disengage the clutch, providing a seamless shifting experience.

11. Hexagonal hole pressure plate: This pressure plate adopts hexagonal hole design, which is easy to install and disassemble.

12. Friction Disc: Contains another friction disc to ensure consistent power transfer and durability of the clutch PTO shaft.

13. Flat Spacers: Flat spacers are used to provide precise alignment and spacing between various components.

14. Nut: Nuts are critical to retaining the bolt and maintaining the integrity of the clutch PTO shaft assembly.

The clutch PTO shaft and its components provide superior functionality to ensure efficient power transfer, durability and ease of use. Manufacturers pay special attention to the quality of the materials used in these components to ensure their reliability and longevity. Regular maintenance and lubrication of the clutch PTO shaft is recommended to extend its service life and ensure optimal performance.

To sum up, the clutch PTO shaft is a key component of industrial and agricultural machinery. Its engagement and disengagement mechanisms and various components enable efficient power transmission. Understanding the characteristics and characteristics of the clutch PTO shaft and its components is critical to the proper operation and maintenance of the machinery on which it is used.

Product Application

The clutch power output shaft is an important component used in various machinery to achieve smooth and efficient power transmission between the engine and equipment. It provides great convenience and versatility for applications such as tractors, construction equipment and industrial machinery. In this article we will explore the various applications and components of the clutch PTO shaft.

One of the key components of the clutch PTO shaft is the pressure plate. This part is responsible for applying pressure to the clutch plate, causing it to engage or disengage the engine. It plays a vital role in ensuring smooth and efficient power transmission.

Another important component of the clutch PTO shaft is the medium-pressure connecting rod plate. This linkage plate connects the pressure plate to the clutch plate, ensuring proper clutch engagement and disengagement. It acts as a bridge between the two components, enabling seamless transmission of power.

The friction disc is another key component of the clutch PTO shaft. It provides the necessary friction to engage the clutch and transfer power from the engine to the equipment. A splined hole connecting rod plate connects the friction plate to the output shaft for a safe and reliable connection.

To ensure proper assembly of the clutch PTO shaft, several additional components are required. These include hex bolts, spring washers, nuts and flat washers. These components are critical to providing the necessary support, adjustment and safe tightening of the various components of the clutch PTO shaft.

In addition to these components, there are other important components that contribute to the smooth operation of the clutch PTO shaft. The medium pressure plate and the hexagonal hole pressure plate cooperate with the friction plate to adjust the engagement and separation of the clutch. Copper sheathing provides durability and reduces friction. The flange yoke connects the clutch PTO shaft to the driven device, enabling power transmission.

To ensure the service life and efficiency of the clutch PTO shaft, regular maintenance and inspection are required. Lubrication of moving parts and regular inspection of components will help identify any signs of wear or damage so they can be repaired or replaced promptly.

In summary, the clutch PTO shaft plays a vital role in various applications, enabling efficient power transmission between the engine and equipment. It consists of pressure plate, medium pressure connecting plate, friction plate, spline hole connecting plate and other components. These components work together to ensure seamless power transfer. To ensure optimal performance of the clutch PTO shaft, regular maintenance and inspections are required. If used and maintained correctly, the clutch PTO shaft proves to be an indispensable component in the mechanical field.

Product Specification